The manufacturing of linear motion guideways generally has bearing steel, carbon steel, stainless steel, and other information. The linear motion guide rail is hardened steel and placed on the device plane after fine grinding. Compared with the plane guide, the CSK linear motion manufacturer designed the shape of the cross-section of the linear guideway to be messier, the reason is that the guide needs to be processed into grooves to facilitate the movement of sliding components. The shape and number of grooves depend on the function of the machine tool to end.

Because of the diversification of the linear motion guideways customers' requirements and different application environment, the linear motion systems made with new materials is presented. For example, the use of stainless steel products, the guide shaft, slider, steel ball, sealing end and adhere to the use of stainless steel data manufacturing, and the reverse use of synthetic resin, so the corrosion resistance is improved.

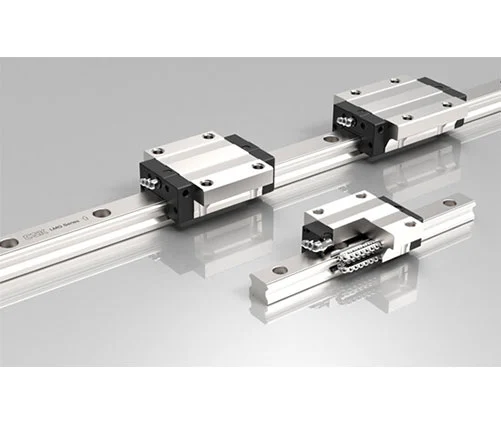

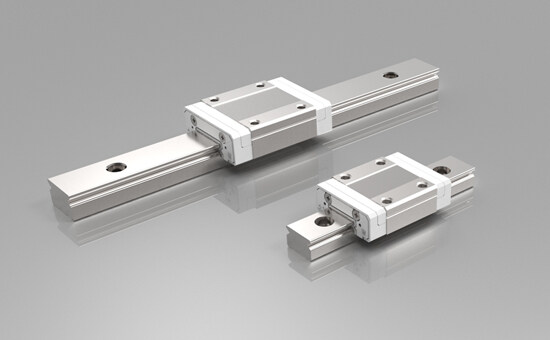

Linear guide is a general term, including slider and track. The linear guide rail also called linear slide rail, stainless steel linear rail, guide rail, or slide rail, actually refers to the same thing. Generally speaking, linear guide rail refers to the square track, there are two or four-track groove guide rails, of course, there are also what people call linear bearings and optical axis linear guide rail, or circular rail. The functions of the stainless steel linear guide rails are:

1, high working accuracy: sports are done by rolling linear guide, not only reduced to 1/50 of the slide guide friction coefficient, but the gap between dynamic and static friction resistance also becomes small, completing the smooth movement, reducing impact and vibration, is not easy to happen the crawling phenomenon, so the level can reach the UM feeding and positioning accuracy, sensitivity and is beneficial to enhance the response speed of numerical control coefficient.

2, greatly reduce the driving rate: because the friction of stainless steel linear guide rail movement is very small, only small power, can make the machine move, significant large power loss of the machine, and the heat due to friction is very small, is suitable for high speed, frequent start and reversing of the moving parts.

3, the lubrication structure is simple: stainless steel linear guide is equipped with an oil filling cup on the slide block, which can be directly injected with oil, and can also be connected with the oil supply pipe to be lubricated by the automatic oil supply machine so that the wear is reduced to less, so that the machine can adhere to the fine work for a long time.

4, dustproof and sealing ability: linear slide guide rail has a good dustproof function, the two ends of the slider are equipped with a sealed end cover, the bottom can choose sealed film, and the screw hole of the sliding rail is equipped with dustproof screw hole cover, to prevent the accumulation of dust, and then ensure the life and function of the product.

5, the device is convenient, simple exchange: because of the selection of precision processing skills, high straightness of the slide rail, the screw hole error of the device in the slide rail is less, the device is convenient, the linear guide rail has exchangeability, can be separated from the replacement of the slide block or slide block or even the linear guide rail, can make the machine to reach high precision again.

6, lm guideways are suitable for all heavy industries and small and medium-sized enterprises that have a demand for stainless linear guides.

This is the first one.