Operation principle of linear guide rail

It can be understood as a rolling lead, which is made of steel balls infinitely rolling cycle between the slider and the guide rail, so that the load platform can easily move along the guide rail with high precision and linear motion, and the conflict coefficient is reduced to one fiftieth of the usual traditional sliding lead, which can easily reach high positioning accuracy. The final unit design between slider and guide rail enables linear guide to accept loads from all directions, such as up, down, left and right together. Patented backflow system and simplified structure design make linear guide smoother and lower noise movement.

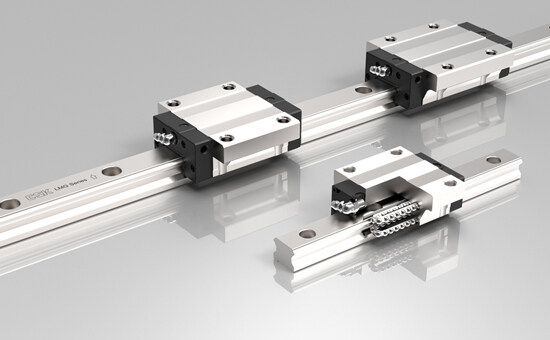

Slider - Changes motion from a curve to a straight line. The new guide rail system enables the machine to obtain fast feed speed. In the case of the same spindle speed, fast feed is the feature of linear guide. Linear guide and plane guide are the same, there are two basic components; One serves as a guide for the fixed element, and the other is a moving element. Because linear guides are standard components for machine tool manufacturers. All Wei needs to do is to process the plane of a equipment guide rail and adjust the parallelism of the guide rail. Of course, in order to ensure the accuracy of the machine tool, a small number of scraping and grinding of the bed or column is essential, in most cases, the equipment is relatively simple. The guide rail is hardened steel and placed on the equipment plane after fine grinding. Compared with the plane guide, the shape of the cross section of the linear guide is messy than the plane guide. The reason for the messy is that the guide needs to be processed into grooving to facilitate the movement of sliding components. The shape and number of grooving depend on the function of the machine tool to be completed. For example, a guide system that accepts both linear forces and overturning moments is compared with one that accepts only linear forces. There's a big difference in design.

Linear slider can be divided into: roller linear guide, cylindrical linear guide, ball linear guide, three kinds, is used to support and guide the moving parts, according to the given direction to do reciprocating linear motion. According to the conflict nature, linear motion guide can be divided into sliding conflict guide, rolling conflict guide, elastic conflict guide, fluid conflict guide and other varieties.

Linear roller guide pair is mainly composed of guide rail, slide block, rolling body (roller or ball) and reverting device. When the slider moves relative to the guide rail, the tumbling body directly rolls in the guide rail and the slider raceway, and through the raceway of the backflow device, from the operating load area to the non-operating load area, and then rolls back to the operating load area, constantly circulating, so as to change the relative movement between the guide rail and the slider from sliding into the rolling of the tumbling body.

In order to prevent dust and foreign matter from entering the guide rail raceway, both ends and the lower part of the slide block are equipped with rubber sealing pads, and the slide block is also equipped with a smooth oiling cup, which can be oiling smoothly to the slide block manually or actively.

The end of the slider can also be equipped with self-smoothing equipment, which does not need to be equipped with smoothing equipment in a certain period of time. Its conflict factor is generally about 2% of the sliding conflict factor, which greatly reduces the conflict loss.