Category: Linear Motion Motor Module

LMB series linear motion motor modules are specially designed for special environments where high and low dust levels are required. A special closed structure is adopted to effectively prevent external foreign bodies from invading the linear motion module body so that it can withstand harsh environments and be protected by long-term effects to prolong the service life of products. The linear motion modules can be connected with special devices to achieve low dust, which can meet the use requirements of a certain level of clean room. A variety of optional configurations from the CSK linear motion manufacturer meet the requirements of different customer groups.

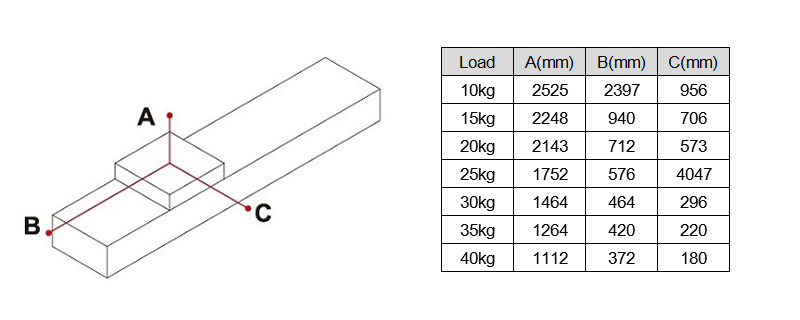

When Used Horizontally

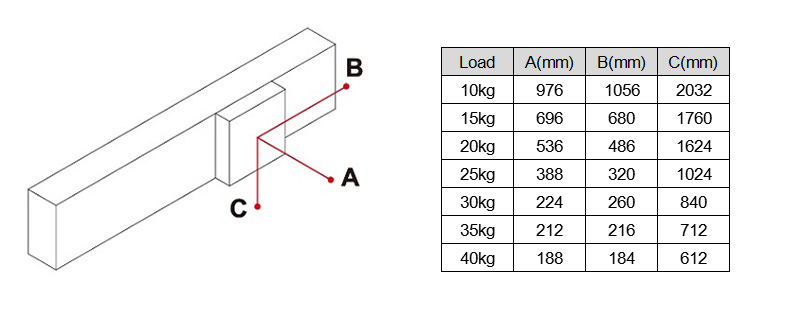

When Used Vertically

The primary advantage is the convenience of single sourcing. This means that all the necessary components such as linear motion systems, screw drives, direct linear drives, digital AC servo motors, digital controllers, and control systems are sourced from a single supplier, ensuring compatibility and reducing procurement hassles.

Another significant benefit is the ideally matched interfaces. This ensures seamless integration of the components, leading to efficient and smooth operations. The modules are designed to provide the right drive for every application, making them versatile and adaptable.

The individual components of the linear motion module are integrated and tuned to match the specific application. This customization ensures optimal performance and reduces the risk of component failure. The high quality of the modules is guaranteed as nearly all of the quality-critical single components are manufactured by Rexroth itself, ensuring reliability and durability.

The linear motion modules are available in any desired length, up to 12 meters in one piece, providing flexibility in application. They also come with optional extras such as adapter plates, brackets, switches, sensor adapters, fasteners, and connectors for mounting to the Rexroth profile system, enhancing their functionality.

Lastly, the reliable global supply and service logistics ensure timely delivery and maintenance of the modules, reducing downtime and enhancing productivity.

14

2022,03

14

2022,03