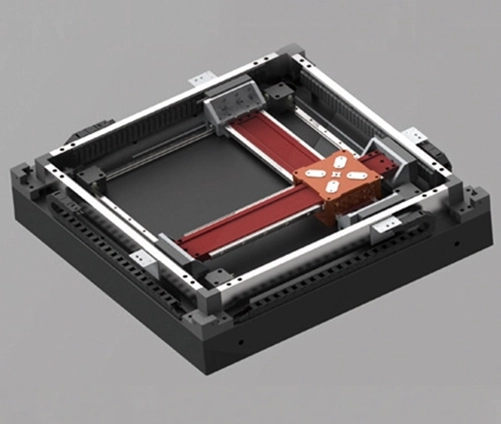

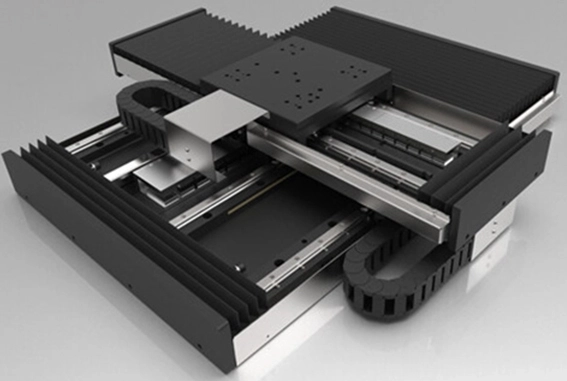

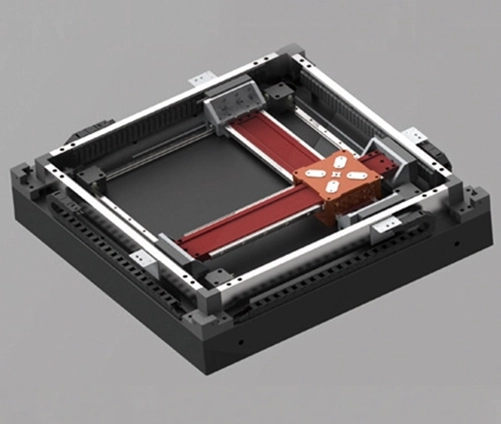

A Linear Motion Platform, also known as a linear motion stage or translation stage, is a mechanical device designed to provide controlled linear motion in various directions. linear motion stage consists of a base, a moving platform or carriage, and a means of actuation. Linear Motion Platforms are commonly used in applications that require precise positioning, scanning, or translation. Contact CSK linear motion manufacturer to know more about linear motion control products.

Travel Range: The required distance the linear motion stages needs to move.

Load Capacity: The maximum weight the linear motion stages can support.

Speed and Acceleration: The desired velocity and acceleration capabilities.

Accuracy and Repeatability: The level of precision required for the application.

Environmental Factors: Considerations like temperature, cleanliness, and vibration sensitivity.

Integration and Compatibility: Compatibility with other system components, such as controllers or software interfaces.

Linear Motion Stages, specifically precision motorized translation stages, are essential components in various industrial and scientific applications, offering high accuracy and minimal runout errors. These motorized linear translation stages range from cost-effective, stepper-motor-driven models suitable for basic positioning tasks, to ultra-high-performance, closed-loop stages with linear encoders that provide nanometer resolution for applications requiring the utmost precision, such as semiconductor manufacturing and photonics instrumentation.

For applications demanding high speed, superior velocity control, and the highest precision, the linear electromagnetic motor is the ideal choice. These eliminate the inefficiencies of converting rotational to linear motion, enhancing performance. Additionally, for the ultimate precision and smoothness over extended travel ranges, direct drive linear stages equipped with air bearings are available, minimizing friction and wear by eliminating mechanical contact.

In essence, the development of linear motion stages caters to a broad spectrum of needs, from basic to highly specialized applications, ensuring there’s a precision positioning solution for nearly any requirement in the realm of industrial and scientific research.

- Precise Positioning: Linear Motion Platforms offer high accuracy and repeatability, allowing for precise positioning of objects or components.

- Smooth and Stable Movement: Linear motion stages provide smooth and stable linear motion with minimal vibration or backlash.

- Flexibility and Customization: Linear Motion Platforms can be customized to meet specific application requirements, including different travel lengths, load capacities, and mounting options.

- Integration: Linear motion stages can be easily integrated into larger systems or workstations.

- Automation Capability: Motorized platforms can be automated and controlled using software or external devices.

- Diverse Applications: Linear Motion Platforms are widely used in areas such as microscopy, metrology, automation, semiconductor manufacturing, laser processing, and research and development.

Base: The foundation of the linear motion stages that provides stability and support.

Carriage or Moving Platform: The component that moves along the linear axis.

Actuation Mechanism: How motion is achieved, such as lead screws, ball screws, linear motors, or belts.

Guide System: Includes precision linear guides, rails, or bearings that provide smooth and precise movement along the desired axis.

Drive Mechanism: Converts rotary motion from the actuator into linear motion, such as a threaded rod or belt drive.