Linear guide rail is also called line rail, slide rail, linear guide rail, linear slide rail,

Used for linear reciprocating motion, with higher rated load than linear bearing, together can bear a certain torque, can complete high-precision linear motion under high load.

Linear motion guide rail is used to support and guide the moving parts, according to the given direction of the reciprocating linear motion. According to the conflict nature, linear motion guide can be divided into sliding conflict guide, rolling conflict guide, elastic conflict guide, fluid conflict guide and so on.

Linear bearings are mainly used in automatic machinery, such as machine tools imported from Germany, paper bowl machines, laser welding machines and so on. Of course, linear bearings and linear shafts are matched. For example, linear guide rails are mainly used in mechanical structures with relatively high accuracy requirements.

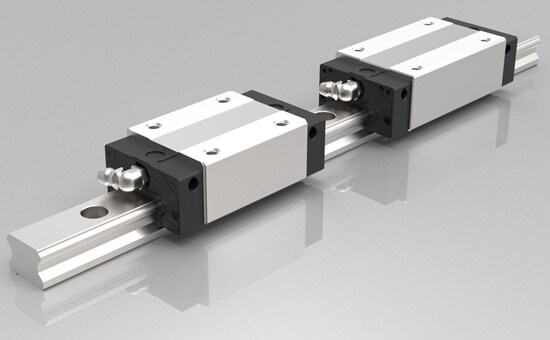

Slider - Changes motion from a curve to a straight line. The new guide rail system enables the machine to obtain fast feed speed. In the case of the same spindle speed, fast feed is the feature of linear guide. Linear guide is the same as plane guide, there are two basic components; One serves as a guide for the fixed element, and the other is a moving element. Because linear guide is a standard part, for machine tool manufacturers. The only thing to do is to process the plane of a guide rail and adjust the parallelism of the guide rail. Of course, in order to ensure the accuracy of the machine tool, a small number of scraping and grinding of the bed or column is essential, in most cases, the device is relatively simple.

The guide rail is hardened steel and placed on the device plane after fine grinding. Compared with the plane guide, the geometric shape of the cross section of the linear guide is messy than the plane guide. The messy reason is that the groove is processed on the guide to facilitate the movement of the sliding components. The shape and number of the groove depend on the function of the machine tool to complete. For example, a guide system that accepts both linear effect force and overturning moment is compared with one that accepts only linear effect force. There's a big difference in planning.

There is no intermediate medium between the moving element and the fixed element of the linear guide, but the rolling steel ball is used. Because the rolling steel ball is suitable for high-speed movement, small conflict coefficient and high sensitivity, it is satisfied with the operation requirements of moving parts, such as the tool rest of machine tools, dragging plates, etc. The basic function of the fixed element (guide rail) of the linear guide system is like the bearing ring, the bracket of the steel ball, and the shape is "V" shape. The bracket wraps the top and sides of the guide rail. In order to support the working parts of the machine tool, a linear guide has at least four supports. For supporting large working parts, the number of brackets can be more than four.

When the working parts of the machine tool move, the steel balls circulate in the groove of the support, and the wear amount of the support is apportioned to each steel ball, thus extending the service life of the linear guide rail. In order to eliminate the gap between the bracket and the guide rail, pre-loading can improve the stability of the guide rail system, pre-loading. A super-sized steel ball is installed between the guide rail and the bracket. The diameter tolerance of the steel ball is ±20 microns, with 0.5 microns as increment, the steel ball is selected and classified, separately installed on the guide rail, and the size of the pre-load depends on the effect of the effect force on the steel ball. If the effect force on the steel ball is too large, the time of pre-loading of the steel ball is too long, resulting in the increase of the movement resistance of the bracket. There is a balancing effect problem; In order to improve the sensitivity of the system and reduce the motion resistance, preloading should be reduced accordingly. In order to improve the motion accuracy and the retention of accuracy, sufficient preloading negative numbers are required, which are the two opposite aspects.

When the operation time is too long, the steel ball starts to wear, and the effect of the pre-loading on the steel ball starts to weaken, leading to the decline of the movement accuracy of the machine tool working parts. If the initial accuracy is to be maintained, it is necessary to replace the guide bracket, or even the guide rail. If the guide rail system has pre-loading effect. System accuracy has been lost by replacing tumbling elements.

The planning of the linear motion control systems, strive to have a large touch area between fixed components and moving components, which can not only improve the carrying capacity of the system, and the system can accept the impact force of intermittent cutting or gravity cutting, the effect force is widely diffused, expand the area of the acceptance force. In order to accomplish this, there are a variety of groove shapes of the guide rail system. There are two representative ones. One is called Gostay (pointed arch), whose shape is the extension of a semicircle and the touch point is the pole. The other is circular arc, the same can have the same effect. No matter what kind of structure form, the purpose is only one, and strive for more rolling steel ball radius with rail touch (fixed elements). The characteristics of the resolution system are: how the tumbling element touches the guide rail, which is the key to the problem.

![CSK Motion [Exhibition Site] - NEPCON ASIA&AWC CSK Motion [Exhibition Site] - NEPCON ASIA&AWC](/uploads/image/20230711/10/the-main-factors-affecting-the-track-accuracy-of-linear-guide_1689041378.webp)