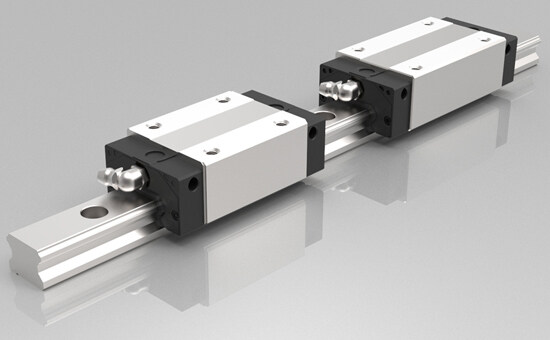

In most modern equipment, there are a large number of linear guide slider, which is the use of the slider in the linear guide to do reciprocating movement principle, although the overall movement trajectory is fixed, and there will be lubricating oil, but because of the different use environment, the slider itself will also have a certain number of problems. Therefore, if the linear guide slide block is damaged, is it repaired or directly replaced?

1. What are the main problems of the slider

Because there are large differences in equipment and environment, it can not be said that the slider will have the same or similar faults in the process of use, but in general, these faults or problems can be divided into two parts, one is the slider motor component part, the other is the guide rail part. In the slider motor components, there are motors, springs, gears and other small parts, very simple problems; In the guide rail part, for example, may cause problems because of rust, deformation and so on.

2, is the choice of repair or replacement

Generally speaking, because most of the slider volume is not large, all kinds of parts are integrated in the installation, so if it is one or several parts of the problem, to the professional repair point can be repaired, but if it is the key parts, perhaps the cost of repair and new almost. In most cases, if there is no problem with the guide rail, it can directly replace the new slider, which is simple and convenient, and the cost is not too high.

3. If it is new, is the price of the slider high

For different equipment slider, there is also a great difference in price, for example, for injection molding machine slider basically 10-20 yuan can be done, and the price of the slider on the carving machine is very high.

The production of rack and pinion needs specific information. The manufacturing process of rack is casting, cutting and heat treatment, etc., because the material should pay attention to the process function of the material in the selection of material. In the face of the data of the process function, we can change the process procedures, heat treatment methods and other ways to improve.

Pinion and rack data needs to choose what? It is necessary to understand the development mode of China's industry, combine China's resources and production conditions, start from the reality, consider the mechanical function, process function and economy and other aspects of the problem, only reasonable material selection can ensure rack quality, reduce product costs, and then improve the market competitiveness.

In order to meet the mechanical function of the data, the mechanical function of the data includes strength, hardness, plasticity and tolerance, reflecting the characteristics of the data in the process of use. When gear meshing, there is contact stress at the tooth surface contact, and the greatest tortuous stress at the tooth root, which may cause tooth surface or tooth body strength failure. Each point on the tooth surface has relative sliding, and wear will occur. The main failure modes of gear include pitting erosion, gluing, plastic deformation and tooth fracture. Therefore, it is required that the gear data have high torsional fatigue strength and contact fatigue strength, the tooth surface should have enough hardness and wear resistance, and the core should have certain strength and endurance. For example, when confirming the hardness of large and small gears, we should pay attention to make the hardness of the tooth surface of the small gear is 30-50hbs higher than the hardness of the tooth surface of the big gear, because the number of loads on the small gear is more than the big gear, and the tooth root of the small gear is thinner, and the strength is lower than the big gear. To make the teeth of the two gears close to equal strength, the tooth surface of the pinion is harder than that of the big one. On the other hand, the trademark of the data is confirmed according to the use function of the data. To clear the mechanical function or hardness of the data, and then we can reach the required hardness scale through different heat treatment processes, and then give different mechanical functions to the data. If the data is 40Cr alloy steel gear, when 840-860C oil quenching, 540-620C tempering, quenching and tempering hardness can reach 28-32HRC, can improve the arrangement, progress and induction of mechanical functions; When 860-880C oil quenching, 240-280C tempering, hardness can reach 46-51HRC, the steel surface wear-resisting function is good, the core resistance is good, small deformation; The hardness can reach 52-54HRC when the nitriding layer is 0.15-0.6mm and the nitriding layer is 500-560C, so the steel has high surface hardness, high wear resistance, high fatigue strength, high corrosion resistance and anti-bonding function, and the deformation is very small. After electroplating or surface alloying, the surface friction function of gear operation can be improved, and the anti-corrosion function can be improved

On the other hand, the trademark of the data is confirmed according to the use function of the data. To clear the mechanical function or hardness of the data, and then we can reach the required hardness scale through different heat treatment processes, and then give different mechanical functions to the data. If the data is 40Cr alloy steel gear, when 840-860C oil quenching, 540-620C tempering, quenching and tempering hardness can reach 28-32HRC, can improve the arrangement, progress and induction of mechanical functions; When 860-880C oil quenching, 240-280C tempering, hardness can reach 46-51HRC, the steel surface wear-resisting function is good, the core resistance is good, small deformation; When the nitriding treatment is 500-560C and the nitriding layer is 0.15-0.6mm, the hardness can reach 52-54HRC, then the steel has high surface hardness, high wear resistance, high fatigue strength, high corrosion resistance and anti-bonding function, and the deformation is very small. After electroplating or surface alloying, the surface friction function of gear operation can be improved. Improved corrosion resistance.