1. Before installing the linear guides rails, it is necessary to remove the burrs, dirt and surface scars of the mechanical device.

Note: the straight slide rail is coated with anti-rust oil before the formal DAO device, please use the cleaning oil to clean the datum before the device, usually after the rust-proof oil is removed, the datum is simple and rusted, so it is recommended to smear the spindle lubricating oil with low viscosity.

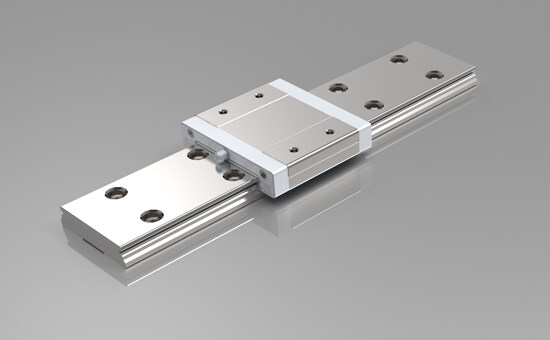

2. Quietly install the main rail on the bed, and use lateral fixing screws or other fixed fixtures to make the rail and lateral device surface quietly fit.

Note: it is necessary to confirm whether the screw hole is in accordance with the device before use. If the base machining hole is not in accordance with the bolt, it will greatly affect the combination accuracy and use quality.

3. Tighten the positioning screws of the slide track slightly from the center to both sides in order to make the track slightly fit the straight device surface. The order is from the beginning of the central direction to the two ends of the force can get more stable accuracy. After the straight datum is slightly tightened, the locking force of the lateral datum is strengthened so that the main rail can really fit the lateral datum.

4. Tighten the positioning screws of the slide rails slowly with a torque wrench according to the locking torque of various materials.

5. Install the secondary rail using the same device method, and slide the individual devices onto the main rail and secondary rail.

Note that after the linear slide on the slide seat device, many accessories cannot be installed due to the limited space of the device, so the required accessories must be installed at this stage. (Accessories may be fuel nozzles, tubing joints, or dustproof systems, etc.)

6. Quietly install the moving channel (table) on the sliding seat of the main rail and the auxiliary rail.

7. First lock the lateral forcing screws on the mobile channel, and proceed in accordance with the sequence after positioning the device.

1, as far as possible bai delay maintenance cycle, shorten downtime, travel labor DU production rate, through the efficient use of zhi to prevent linear guide rust.

2. Under the high speed dn > 5×105, dao should ensure low motor temperature rise, no oil dumping, and then reduce power consumption to maintain the motor.

3, its pure content control is under certain specifications, reduce equipment noise pollution to the situation.

4, under the premise of ultra-low temperature work to ensure the linear guide start and work spirituality, to ensure the minimum output power.

5. The cleaning of the removed deep groove ball bearings is divided into coarse cleaning and fine cleaning. They are placed in the container, and the metal mesh bottom is put first, so that the bearing does not directly touch the dirt of the container.