Entering the era of innovation in the 21st century, China's industrial level has continuously increased several times and is about to enter the 4.0 technology. Technological skills continue to improve, traditional enterprises gradually phased out, more is to turn to artificial machine operation. Today we dongguan Heathke technology xiaobian, and we share, the use of such a high fine transmission, its inside the component is how, how the structure, let's discuss it together!

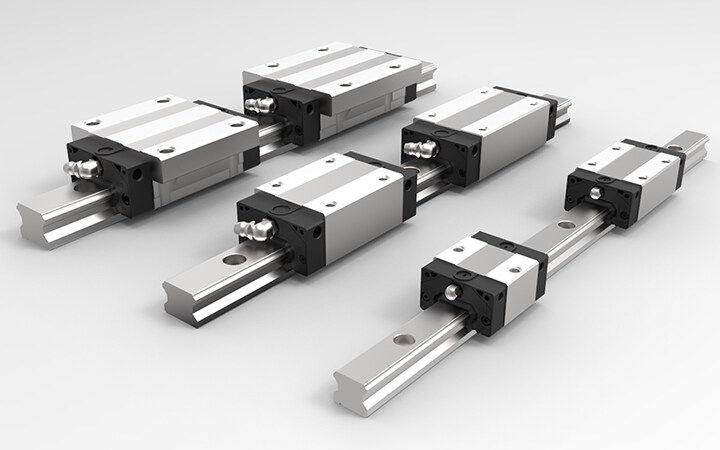

Insert Roller, Needle Guide Rail Structure

inserted roller linear guide pair is composed of two guide rails with V-shaped raceway, roller cage, cylindrical roller, etc., interspersed with each other cylindrical roller in the v-shaped raceway surface through fine grinding reciprocating movement, can withstand the load in all directions, complete high precision, smooth linear movement.

needle roller linear guide pair is composed of two concave and convex tracks, a 90 degree Angle cage, cylindrical needle roller, etc. Two rows of needle roller do reciprocating movement on the convex track through grinding. Due to the dense arrangement of needle roller, high precision, heavy load, smooth linear movement can be completed.

(1) Low rolling friction resistance and good stability;

(2) Small starting friction and good follow-up performance;

(3) Large touch area, small elastic deformation, more useful moving body, easy to complete high rigidity, high load movement;

(4) Flexible structure design, easy to use device.

Specifications: Japanese specifications, Swiss specifications, Philippine international specifications (drawings provided by customers)

Cage: steel cage, nylon cage, V cage.

![CSK Motion Technology [Exhibition Site] - Shanghai Industrial Expo CSK Motion Technology [Exhibition Site] - Shanghai Industrial Expo](/uploads/image/20230711/10/the-main-factors-affecting-the-track-accuracy-of-linear-guide_1689041378.webp)