Solution of oil leakage in grinder for linear guide rail. The two ends of the worktable dustproof plate gold oil, generally is not careful installation of special grinder, fixed dustproof plate gold screw through the guide rail at both ends, oil directly from the guide rail, the solution is special grinder screw wrapped tape to play dense glue.

It may be that the oil quantity is too large to adjust. After opening the oil groove cover, use a flat-head screwdriver to adjust the oil valve switch respectively. Clockwise is to adjust small; otherwise, it is to adjust large.

The oil groove on the wear-resistant piece of the special grinder for precision linear guide rails is not well opened, opened too shallow or not in place, the oil can not overflow from the side, should be opened from the beginning in place; The oil hole is blocked, the oil is forced out of the guide rail, the oil hole is blocked generally because the oil is too sticky or too dirty. Replace the oil or finish the oil path. If it is the old surface grinder, the guide rail is too dirty and the oil path is blocked.

The dustproof plate at both ends of the workbench is gold seeping oil. It is generally not careful to install the special grinder for linear guide rail. The screw fixed to the dustproof plate gold penetrates the guide rail at both ends and directly seeps oil out of the guide rail. The float action of mercury switch is not agile, so that the oil return is blocked. The buoyancy of float action should be improved to make the oil return channel smooth.

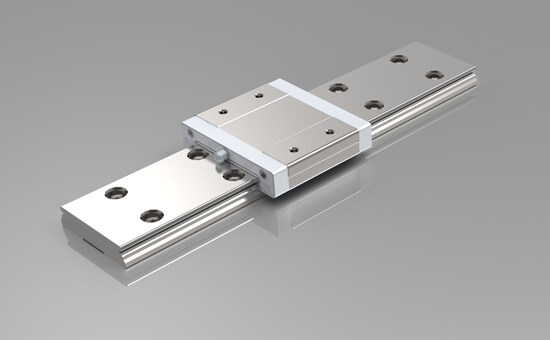

Introduction of linear guide rail and slide block. Linear guide rails are used for linear reciprocating motion and can achieve precision linear motion under high load. Linear motion guide rail is used to support and guide the moving parts, according to the given direction of the reciprocating linear motion.

Linear guide is mostly used in automation machinery, for example: laser machine profession, professional glue, industrial machinery, plastic machinery, printing machinery, papermaking machinery, etc.), electronic machinery, in high-speed transport equipment, medical equipment, game consoles, film career, furniture profession, linear guide as industrial parts, is widely used.

Company of linear guide slider roughly divided into three types of flange sifang high assembling sifang low assembled, each type has two different scales (flange standard king-size, sifang assembled type points higher standard, lengthened the quartet low assemble type points short type standard), correspond to the same scale of guide rail, a linear guide at the different scales have different usage scenarios, 15-25 medium and small size guide is suitable for small equipment, such as manipulator, 30-45 size guide has a large bearing capacity, suitable for large equipment.

Because of the wide range of use scenarios of linear guide and the continuous improvement of the level of mechanization in China, the market prospect of linear guide is increasing in China, and the development of domestic linear guide has driven the development of other manufacturing operations, domestic demand is increasing, and the market of linear guide in China is getting bigger and bigger.

This is the last one.