In the realm of modern engineering and automation, the linear electric motor stands as a pivotal innovation, driving the advancement of various industries with its efficiency and precision. CSK Motor Stator Manufacturers, a leader in the field, delves into the essentials of linear electric motors, exploring their fundamental principles, diverse applications, operational mechanics, speed capabilities, and frequency characteristics. This article aims to illuminate the intricacies of linear electric motors, offering insights into their transformative potential.

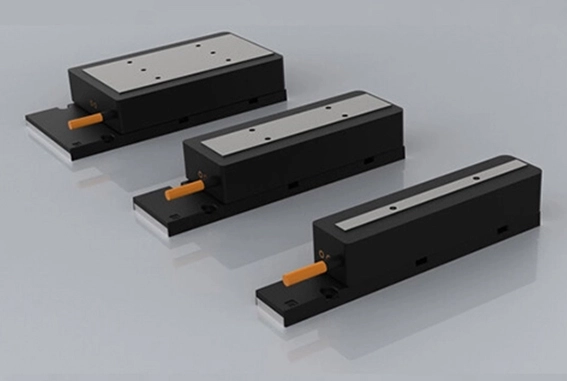

At its core, a linear electric motor is designed to produce motion in a straight line, contrasting with the rotational output of traditional electric motors. This type of motor utilizes the principles of electromagnetism to generate linear force, leveraging an electric motor stator and a movable part, often referred to as the slider or plunger. The key components include the motor stator, which is embedded with coils that create a magnetic field when energized, and the mover, which interacts with this magnetic field to produce motion. CSK Motor Stator Manufacturers specializes in crafting high-quality stators that are essential for the efficient operation of linear electric motors.

The versatility and efficiency of linear electric motors have led to their widespread adoption across various sectors. Notably, they are employed in precision machining and assembly lines, where their ability to deliver precise, controlled motion enhances operational accuracy and productivity. Additionally, linear electric motors are integral to the transportation sector, powering advanced systems like maglev trains, which achieve remarkable speeds through electromagnetic propulsion. Other applications include medical devices, where they facilitate precise movements in equipment such as MRI machines, and in the entertainment industry, driving motion platforms in virtual reality setups and theme park rides.

The operation of a linear electric motor is grounded in electromagnetic principles. When current flows through the coils within the electric motor stator, it generates a magnetic field. The interaction between this magnetic field and the magnets or ferromagnetic materials in the mover creates a force that propels the mover along the length of the motor stator. This direct conversion of electrical energy into linear motion eliminates the need for additional mechanical components, reducing energy loss and enhancing efficiency. CSK Motor Stator Manufacturers’ expertise in stator design ensures optimal performance of linear electric motors, maximizing the efficiency of this electromagnetic interaction.

The speed of a linear electric motor is a critical parameter, reflecting its ability to perform tasks quickly and efficiently. Linear electric motors are capable of achieving high speeds, with some models reaching velocities of several meters per second. The actual speed attainable by a linear electric motor depends on various factors, including the design of the motor stator, the strength of the magnetic field, and the load being moved. CSK Motor Stator Manufacturers employs advanced design and manufacturing techniques to optimize the speed capabilities of their linear electric motors, catering to the high-speed requirements of modern industrial applications.

| Linear Motor Type | Typical Speed Range | Applications |

| DC Brush | Up to 2.5 m/s (100 in/sec) | Long strokes, open or closed-loop servo applications |

| Linear Induction Motor (LIM) | Up to 45 m/s (1800 in/sec) | High-speed applications like maglev trains, roller coasters |

| Synchronous Linear Motor | Up to 2 m/s | Machine tools requiring high precision and smooth motion |

| Linear Servo Motors | Up to 3.4 m/s | Applications needing fast acceleration and precise positioning |

The frequency of a linear electric motor refers to the rate at which the current in the motor stator’s coils is alternated, directly influencing the motor’s speed and force output. Higher frequencies can lead to faster movement of the mover, but they also require careful management to prevent excessive heat generation and energy loss. The optimal frequency for a linear electric motor varies based on application-specific requirements, including the desired speed, load, and operational efficiency. CSK Motor Stator Manufacturers leverage sophisticated engineering to fine-tune the frequency characteristics of their linear electric motors, ensuring they meet the precise needs of each application.

| Parameter | Description | Units | Typical Range |

| Supply Frequency (AC Motors) | Frequency of the AC current powering the motor | Hz | 50 Hz or 60 Hz (depending on region) |

| Resonant Frequency | Natural frequency of motor vibration | Hz | 150 Hz - 300 Hz (example range, can vary depending on motor design) |

Linear electric motors represent a transformative technology, offering unparalleled precision, speed, and efficiency in a wide range of applications. From revolutionizing transportation with maglev trains to enhancing precision in medical devices, these motors are at the forefront of innovation. CSK Motor Stator Manufacturers stands as a key player in this field, providing expertly crafted motor stators that are integral to the performance of linear electric motors. By understanding the basics, applications, operational mechanics, speed, and frequency of linear electric motors, industries can harness their full potential, driving forward technological advancement and operational excellence.