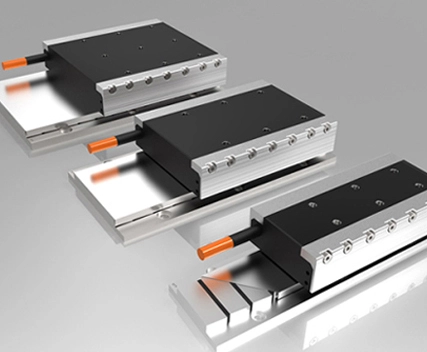

Linear motion control products refer to a mechanical device or system designed to facilitate linear movement along a specific path. The linear motion control products encompass a wide range of components, such as linear guides, linear motion guide actuators, ball screws, and linear motion bearings. These linear actuator motion products are crucial in various industries where precise and smooth linear motion is required, including manufacturing, automation, robotics, and transportation. Linear motion control products enable controlled and accurate movement in one dimension, offering benefits such as increased productivity, improved efficiency, and enhanced positioning accuracy. The motion systems linear actuators play a fundamental role in transforming rotary motion into the linear motion components, and linear motion equipment/devices of the CSK linear motion manufacturer provides solutions for diverse applications and ensures smooth and reliable operation.

Industrial Automation

Linear actuator motion products are extensively used in industrial automation systems for precise positioning, assembly line operations, and material handling applications.

Robotics

Actuated linear motion systems actuator products enable smooth and controlled movement in robotic systems, facilitating tasks such as pick-and-place operations, linear motion control actuators for robotic arms, and linear actuator motion for autonomous mobile robots.

CNC Machining

Linear actuator motion guides and ball screws are crucial components in CNC (Computer Numerical Control) machines, providing accurate and repeatable precision linear motion for cutting, milling, and engraving operations.

Packaging and Printing

Linear actuator motion products are employed in packaging and printing equipment to ensure precise movement of materials, such as conveyor systems, label applicators, and printing heads.

A linear motion guide actuator, such as those produced by CSK, is a device that creates motion in a straight line, as opposed to the circular motion of a conventional electric motor. The working principle of a linear motion guide actuator is based on the concept of an inclined plane and begins with a threaded lead screw, which acts as a ramp to generate force.

The lead screw is connected to a motor, which when activated, rotates the screw. As the screw rotates, it moves along the threads of a nut that is prevented from rotating but is allowed to move linearly. This action converts the rotational motion of the motor into linear motion, allowing the motion control linear actuator to push or pull a load along a straight path.

The purpose of any motion control linear actuator design is to provide push or pull motion. Depending on the application, the actuator can be designed to deliver a specific amount of force, speed, or precision. For instance, some actuators are designed to move heavy loads at slow speeds, while others are designed for high-speed, precision movements.

A linear motion guide actuator, like those manufactured by CSK, works by converting the rotational motion of a motor into linear motion using a lead screw and a nut. This simple yet effective mechanism allows for precise control of linear movement, making motion systems linear actuators a vital component in a wide range of applications.

The key difference between a linear actuator motion product and a linear actuator rotary motion product is the type of motion they enable: linear actuator motion products facilitate movement in a straight line, while linear actuator rotary motion products enable circular or rotational motion.

Yes, linear motion products may require special maintenance such as lubrication, cleaning, and periodic inspection to ensure optimal performance and longevity.

To choose the right linear motion product, factors such as load capacity, speed requirements, accuracy, environmental conditions, and desired lifespan need to be considered, along with the specific application requirements and compatibility with other system components. Consulting with experts or manufacturers can help in selecting the appropriate linear motion product for a particular application.